Purchasing a used Swiss lathe machine can be a cost-effective way to expand manufacturing capabilities, but it requires careful inspection to ensure reliability and precision. A thorough evaluation helps identify wear, damage, or maintenance issues that could affect performance. Understanding the key aspects to check will ensure that the investment delivers long-term value.

Visual Examination

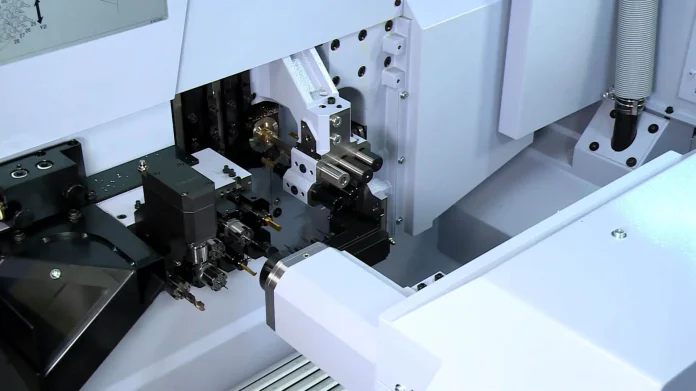

Start with a detailed visual inspection of the machine. Examine the frame, guide bushings, spindle, and tool holders for signs of wear, corrosion, or physical damage. Look for oil leaks, loose bolts, and worn belts, which may indicate poor maintenance. Check for signs of excessive vibration or misalignment, as these can impact machining accuracy. A clean and well-maintained exterior often reflects how well the machine has been cared for internally.

Checking Mechanical Components

Assessing the mechanical components is critical for evaluating performance. Rotate the spindle by hand to ensure smooth operation and listen for unusual noises. Inspect the lead screws, ball screws, and linear guides for wear or backlash. Check the movement of the carriage and turret to verify that it slides smoothly and maintains alignment. Functionality of the tool holders, chucks, and bar feeders should also be tested to ensure they are secure and operate correctly.

Assessing CNC and Electronic Systems

For CNC-equipped Swiss lathes, evaluating the electronic control system is essential. Check the condition of the control panel, wiring, and connections. Ensure the software is up to date and that all functions, including multi-axis operations and live tooling, are responsive. Testing the machine with a simple program allows you to verify that the axes move accurately, commands are executed correctly, and the system provides reliable feedback. Reputable suppliers often provide a detailed operational history or inspection report, such as from a swiss lathe machine, to support the assessment.

Test Run and Performance Check

Running a test part is one of the most effective ways to evaluate the machine’s capabilities. Choose a workpiece similar in material and complexity to those you intend to produce. Inspect the finished part for dimensional accuracy, surface finish, and consistency. Evaluate cycle times, tool changes, and spindle performance during the test run. Any deviation from expected results could indicate wear or calibration issues that need to be addressed.

Maintenance and Service Records

Reviewing maintenance history provides insight into how the machine was cared for. Regular lubrication, alignment checks, tool replacements, and software updates indicate proper upkeep. Machines with complete service records are generally more reliable and may require fewer immediate repairs. Conversely, lack of documentation may suggest potential hidden issues or neglect.

Checking for Wear and Replacement Parts

Certain components, such as guide bushings, spindles, and drive belts, are subject to wear and may need replacement over time. Inspect these critical parts for signs of fatigue or damage. Confirm that replacement parts are available and reasonably priced, as this will affect the cost of keeping the machine in service. Machines that are difficult to service or have rare components can lead to costly downtime.

Safety Features and Compliance

Even for used equipment, safety should not be compromised. Check emergency stop buttons, interlocks, guards, and chip containment systems to ensure they function correctly. Confirm that the machine meets current safety standards, as non-compliance could pose risks to operators and may require additional investment to upgrade.

Documentation and Warranty

Request manuals, schematics, and any available warranties. Proper documentation provides guidance for operation, maintenance, and troubleshooting. A limited warranty from a reputable seller can offer added assurance, especially if the machine is refurbished or has undergone significant repairs.

Conclusion

Inspecting a used Swiss lathe machine involves careful evaluation of mechanical components, CNC systems, wear, maintenance records, and safety features. Performing test runs and reviewing documentation ensures that the machine can deliver reliable, high-precision performance. By following these steps, manufacturers can make informed decisions, minimize risks, and secure a used Swiss lathe that supports consistent quality and long-term operational efficiency.