In today’s rapidly evolving textile industry, customization and creativity have become key drivers of business growth. One of the most impactful innovations helping manufacturers and entrepreneurs achieve this is the Sock Printer. With advanced printing technology, businesses can now produce high-quality, vibrant, and personalized socks efficiently and at scale. However, selecting the right machine can be challenging given the wide range of models and specifications available. This guide explores the essential factors to consider when choosing a sock printer that fits your production goals, budget, and design requirements.

Understanding What a Sock Printer Does

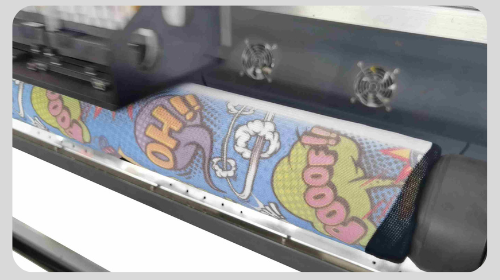

A sock printer is a specialized digital printing machine designed to print directly onto socks with precision and vibrant color reproduction. Unlike traditional embroidery or weaving methods, digital sock printing allows businesses to create detailed, full-color designs, logos, and images quickly and cost-effectively.

If you are planning to invest in this technology, working with a trusted supplier such as Sock Printer experts ensures you receive reliable equipment backed by technical support, customization options, and advanced printing features. These suppliers provide solutions that cater to both small startups and large-scale textile manufacturers.

Key Factors to Consider When Choosing a Sock Printer

1. Printing Technology

The first thing to understand is the type of printing technology that best suits your business needs. The most common options include:

- Sublimation Printing: Ideal for polyester-based socks, this method provides vibrant and durable prints that resist fading.

- Direct-to-Garment (DTG) Printing: Works well for cotton and blended fabrics, offering high-resolution images and smooth finishes.

- UV Printing: A newer method that allows printing on various materials and provides excellent color depth and durability.

Each technology has unique advantages, so selecting the right one depends on your product line and fabric type.

2. Print Resolution and Quality

High-resolution output is critical for achieving professional-grade results. Look for printers with at least 1200 DPI (dots per inch) to ensure sharp images and detailed graphics. Some premium models offer even higher resolutions for intricate designs, gradients, and photo-quality prints.

3. Production Speed and Efficiency

Speed plays a crucial role in determining your production capacity. If your business handles bulk orders, consider a machine that can print multiple pairs simultaneously without compromising quality. Automated feeding systems and fast-drying inks can further enhance productivity while reducing downtime.

4. Ink Type and Color Options

Different printers use various ink types—such as water-based, pigment, or sublimation inks—each suited for specific materials. Ensure the inks are eco-friendly, quick-drying, and resistant to washing. A wide color gamut is also essential for creating vibrant designs and maintaining brand consistency.

5. Material Compatibility

Not all printers are compatible with every fabric type. Verify that the machine you choose can handle the kinds of socks you plan to produce—whether cotton, polyester, nylon, or spandex blends. Some advanced models are versatile enough to print on multiple materials without additional setup.

6. Maintenance and Support

Ongoing maintenance and after-sales support are vital for ensuring the longevity and consistent performance of your machine. Choose a manufacturer that offers easy-to-clean components, replaceable print heads, and responsive customer service. Regular servicing and software updates can prevent costly downtime and extend the printer’s lifespan.

7. Cost and Return on Investment

While high-end sock printers may come with a larger upfront cost, they often provide better performance, durability, and lower long-term expenses. Assess your expected production volume and pricing strategy to determine which machine offers the best return on investment.

Benefits of Investing in a High-Quality Sock Printer

Purchasing a professional sock printer offers numerous benefits for both small businesses and established manufacturers:

- Customization: Create unique designs for brands, events, and individual customers.

- Scalability: Easily expand your production capacity as your business grows.

- Reduced Waste: Digital printing minimizes excess material and ink usage, making it environmentally friendly.

- Faster Turnaround: Shorter setup times enable quicker production cycles and on-demand manufacturing.

- Brand Differentiation: Offer personalized and high-quality products that stand out in competitive markets.

Future Trends in Sock Printing Technology

As digital printing technology continues to evolve, the sock printing industry is expected to see even more advanced features. Future printers will likely include AI-based design optimization, improved energy efficiency, and integrated automation systems for seamless operation. Additionally, sustainable materials and eco-inks will play a larger role in meeting global environmental standards.

Conclusion

Choosing the right Sock Printer for your business requires careful consideration of technology, speed, cost, and support. By understanding your production needs and working with a trusted supplier, you can make an informed investment that enhances efficiency, creativity, and profitability. As demand for customized apparel continues to rise, adopting advanced sock printing technology will position your business at the forefront of innovation in the textile industry.